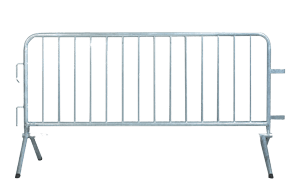

WHAT ARE INTERLOCKING METAL BARRICADES?

The original concept for interlocking metal barricades was patented in France in the early 1950s and produced by Samia SA.

Samia is now out of business, and the concept is in the public domain.

Samia licensed foreign companies to produce metal barricades for crowd control. Various local changes resulted in some variations – three that remain popular in the United States, plus a fourth variation from Canada.

Request a Quote for Classic Steel Barricades

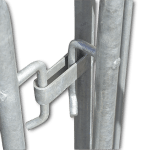

The objective was to make two frames connect in such a way that, in a line, no single frame could be removed from the line.

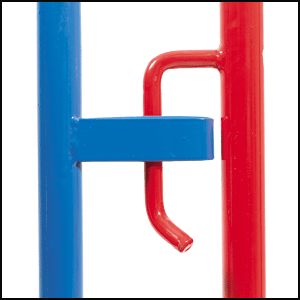

Samia accomplished this with a bend in the top male hook, which would enter a female receiver at an angle of about 30 degrees. Thus, when the frame was straightened, the “tip bend” would not have the space to be pulled out.

There is a correlation between the diameter of the male hook and female receiver. If the receiver is too small, it will not allow the connection. If it is too large, the hook will be able to be lifted out.

These variations explain why so many of the orphans on the market do not correctly connect, even when they are in the same relative position on the ground.

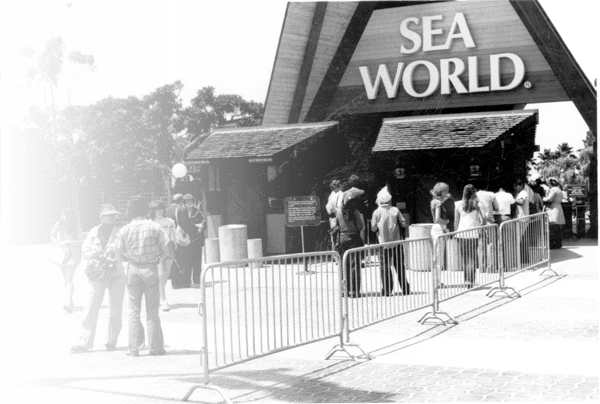

In the early 1970s, the Blockader trade name started to gain attention with a redesigned and innovative style of metal barricades introduced at major public sites in California.

More than 30 years after its debut at SeaWorld, Disneyland, Knott’s Berry Farm, and the Orange County Fairgrounds, the Classic Blockader crowd control barrier stands as the longest continuously available style of crowd control barrier in the United States.

Blockader established a successful and recognizable brand name because it set a new standard for the design and fabrication of metal barricades.

During this time span, the competitive environment in the crowd control equipment market had undergone radical shifts approximately every ten years. Most of the companies selling metal barricades today did not exist ten years ago. But one thing remains constant – new entrants to the field all model (or sometimes copy outright) their product’s design and accessories after the pioneering Blockader style.

Blockader established a successful and recognizable brand name because it set a new standard for the design and fabrication of metal barricades. The Blockader model introduced in the 1970s improved upon the original French patent for the product by featuring a few instantly-popular upgrades.

SINCE 1976 – BLOCKADER CROWD CONTROL BARRICADES

Blockader metal barricades have changed the way America handles crowd control.

Blockader barriers have come to be regarded as the industry standard for quality, reliability and customer service.

IMPROVEMENTS IN CROWD CONTROL BARRIERS

Blockader has been a pioneer in the metal barricade industry for almost 30 years. We’ve continually introduced new innovations which have made steel crowd control barriers a more effective, customer-friendly crowd management tool.

Every new concept which has improved metal barricades was introduced into the marketplace by Blockader. That’s why you should buy metal barricades from us!

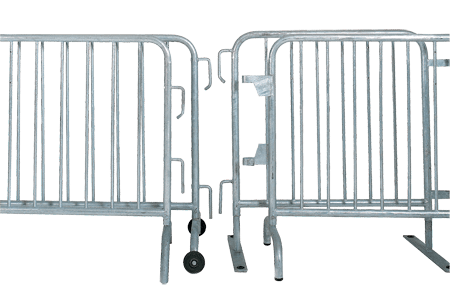

1977 – REPLACEABLE BASES

The introduction of interchangeable bolt-on replacement bases for steel barricades enabled users to replace a base instead of replacing an entire barrier.

1978 – WHEEL BASE

The introduction of wheelbases made steel barriers easier to move and reposition, increasing options for their use during an event.

1986 – PAINTED BARRIERS

Moving beyond silver/grey, barriers painted with bright colors stand out aesthetically, while the paint adds to the barrier’s life-span.

1987 – DIFFERENT LENGTHS

Blockader established the now-standard lengths for steel barricades: 1-meter, 2-meter, and 2.5-meter lengths.

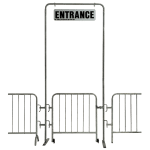

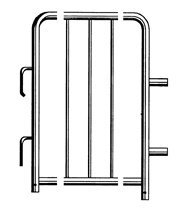

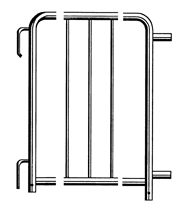

1986 – GATES AND ARCHES

Gates and arches add functionality to a line of steel barriers, providing emergency access and denoting designated entrances.

1990 – HIGH BARRIER

Blockader pioneered the 8-foot high portable steel barricade, a stable fencing option which many sports stadiums have adopted.

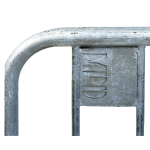

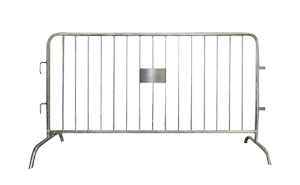

1991 – LASER-CUT SIGNS

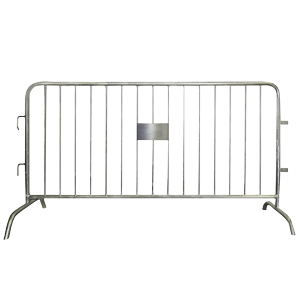

Steel signs which are embedded in the barrier identify ownership, discourage theft, and enable more accurate inventory control.

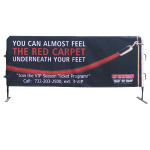

1992 – BARRIER JACKETS

Vinyl barricade covers can feature the logo or message promoting a venue, event, or sponsor, becoming attractive ground-level billboards.

1993 – SQUARE STACKING BARRIERS

Square stacking metal

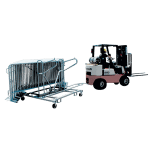

1994 – BARRIER CARTS

Carts efficiently transport Blockader metal barricades, saving labor costs and time.

1998 – RUBBER STOPPERS

Rubber inserts on barrier bases result in damage-free indoor use and reduce sliding on smooth surfaces.

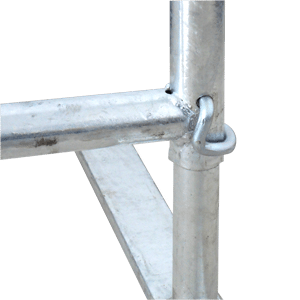

1998 – RIGHT-ANGLE CONNECTION

Hooks on Blockader barriers are designed to enable three steel barriers to be connected at one point.

2009 – QUICK CLIP

This pin slides into the bolt hole of a barrier, allowing a base to be easily connected without the need for a bolt. Bases can be quickly connected to or disconnected from frames making set-up fast and easy.

2010 – LIGHTWEIGHT, ECONOMICAL “STANDARD” BARRIER

Blockader introduced the Standard Barrier this lower-priced yet high-quality metal barricades specially designed for line delineation purposes. It interlocks with classic barriers and is easy to move.

Request a Quote for Classic Steel, Interlocking Metal Barricades

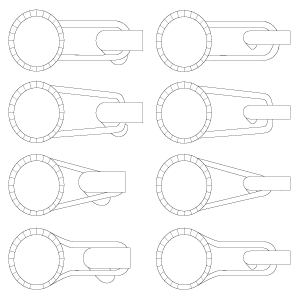

THREE POPULAR INTERLOCKING METAL BARRICADE HOOK STYLES

You can make sure that the purchase of a new steel barrier will be compatible with your existing stock by matching the barricade’s hook style.

Classic Style

The most popular style has the male hooks approximately 15 inches apart

Wide Hook Style

This style features male hooks that are approximately 25 inches apart

Bent Hand Style

These barriers are simple to connect, but cannot accommodate arches or gates

“ORPHAN” HOOKING STYLES

Question about which hook style will be best for your bike rack barriers?

Unfortunately, there are many interlocking metal barricades which feature non-standard hook variations, resulting in incompatibility with the most popular bike rack barricades. Many were produced by fabricators which have since gone out of business.

Blockader can produce compatible barriers for you when the correct hook style on your existing crowd control barricade can be identified.

In almost all cases, we can meet your needs cost-effectively. Call us to speak with a specialist who will take the time to understand your situation and arrive at an answer that works for you.

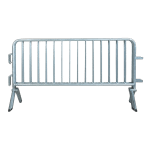

Advantages of Blockader Interlocking Metal Barricades

The Blockader philosophy is quality first. Buy metal barricades from Blockader.

16 gauge steel in both the frames and the bases.

Stronger Steel prevents deterioration and distortion, without adding excess weight to the barrier.

Bolt-on replaceable bases.

Enables easy replacement – simply replace the base of the barrier and not the entire barrier itself.

Male hooks inserted into and welded to the frame at both ends.

Results in hooks which last much longer than single-welded hooks.

Vertical bars (uprights) inserted into frames before welding.

Inserting before welding is a superior technique to spot welding (which results in easier breakage).

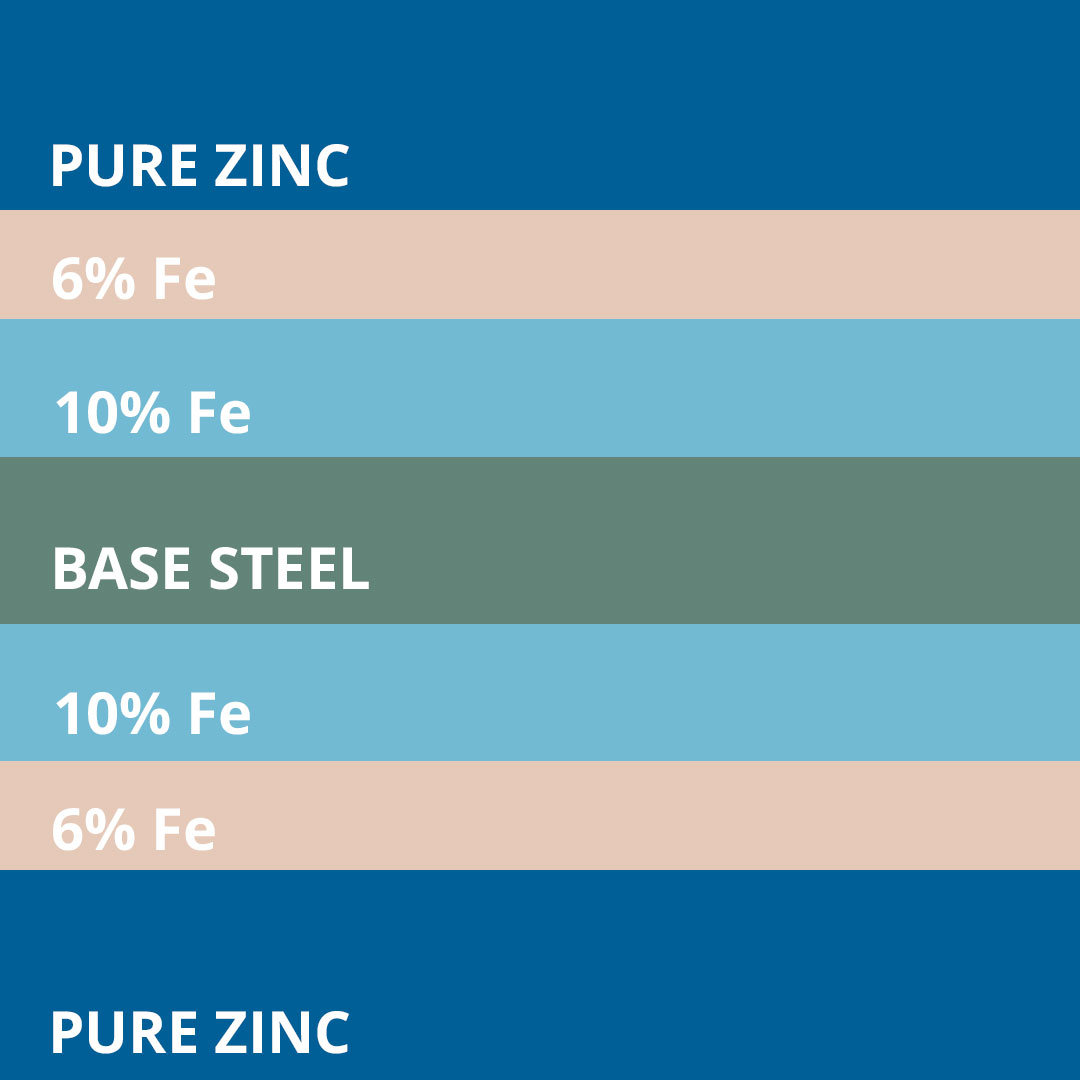

Hot-dip galvanizing.

The best protection for steel, resulting in a longer life span for your barriers. Barriers that are merely painted will rust.

Saddle-Cut Welds.

Much stronger than simple spot welding, saddle-cut welding results in superior strength and durability.

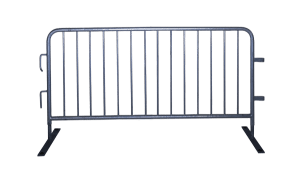

BLOCKADER STEEL BARRIERS Are Available in Three Styles

These are all interlocking metal barricades.

Looking for covers for your barriers? Head over to our Barrier Jackets division website.