The Best Corrosion Protection for Steel Barriers

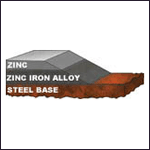

Our barriers are hot dip galvanized, inside and out, to create a

true zinc alloy coating.

Galvanizing increases a barrier’s lifespan

- Hot dip galvanized steel lasts four times longer than painted steel

- Galvanized barriers can remain corrosion and rust-free for 40 years

INSIDE AND OUTSIDE PROTECTION

- Painted steel will corrode from both inside and out when exposed to moisture or corrosive elements

- Galvanizing forms a metallurgical alloy as zinc flows inside the tubing as well as outside

THE PROCESS OF GALVANIZING STEEL BARRIERS

- A zinc coating is applied to the steel by immersing it in a bath of molten zinc (at 850 degrees)

- Barriers are carefully cleaned prior to galvanizing to ensure 100% coating

- Molten zinc naturally reacts with the surface of the steel to form a series of zinc-iron alloys that protect the underlying steel from corrosion

A SMART INVESTMENT

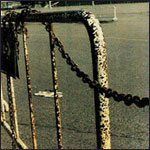

Steel that is merely painted will corrode from the inside when exposed to moisture or other elements. The hot dip galvanizing process pays off in the long run by significantly increasing the barriers’ lifespan.

AVOID THIS

Many non-standard “knock-off” barriers are only painted, not hot dip galvanized. The paint is only a cover – it will chip and peel, and then corrode from the inside.

Specify barriers that are hot dip galvanized to guarantee that you’ll receive long-lasting, corrosion-free barriers. For more details on the galvanizing process, visit the American Galvanizers Association.